In hazardous areas with explosion risks, it is not sufficient for fire detection and alarm systems to comply only with product performance standards such as EN 54; the equipment must also be certified to operate safely in explosive atmospheres. The European Union’s ATEX Directive (2014/34/EU), along with the parallel international IEC 60079 series, defines this safety.

In many industries such as refineries, petrochemicals, grain silos, flour mills, battery production, LNG/LPG facilities, and dusty processes, explosive atmospheres caused by flammable gases/vapors and/or dust can occur either periodically or continuously.

In such environments, fire detection systems face two main risks:

- Becoming an ignition source themselves (spark, hot surface, static electricity, etc.),

- Explosion resistance and operational continuity (integrity after an explosion, sealing according to the protection method).

ATEX certification verifies the equipment’s ability to manage these risks. Thus, alongside EN 54 performance requirements, the dimension of “safety in explosive atmospheres” is also guaranteed.

Basics of ATEX: Scope, Marking and Compliance

ATEX 2014/34/EU regulates the design, production, and conformity assessment of equipment and protective systems intended for use in explosive atmospheres. At this point, important classifications are made:

1- Equipment Groups

Group I: Underground mines and environments with firedamp (methane) risks.

Group II: Surface industrial plants where gases and vapors are present.

Group III: Surface industrial plants where combustible dust is present.

2- Equipment Categories

Category 1: Very high protection (Zone 0 or Zone 20 – continuous explosive atmosphere).

Category 2: High protection (Zone 1 or Zone 21 – where explosive atmosphere is likely to occur).

Category 3: Normal protection (Zone 2 or Zone 22 – where explosive atmosphere occurs rarely).

3- Types of Explosive Atmospheres (Gas/Dust)

G: For gas and vapor atmospheres.

D: For dust atmospheres.

4- Gas Groups

IIA: Less hazardous gases such as propane.

IIB: Medium-hazard gases such as ethylene.

IIC: Most hazardous gases such as hydrogen and acetylene.

5- Temperature Classes (T1–T6)

Defines the maximum surface temperature of a device:

T1: 450 °C

T2: 300 °C

T3: 200 °C

T4: 135 °C

T5: 100 °C

T6: 85 °C

The surface temperature must remain below the ignition temperature of the explosive gas.

Protection Methods and Their Relation to Fire Detection Components

Ex i (intrinsically safe): Circuit energy and temperature are limited below ignition level. Addressable/conventional detectors and manual call points are often chosen as Ex i. Intrinsically safe loops are designed with galvanic isolators or Zener barriers (EN 60079-11).

Ex d (flameproof): The enclosure contains the internal explosion and prevents the flame from escaping. Commonly used in sirens, flashers, and combined sounder-beacons requiring higher power.

Ex e (increased safety): In equipment that normally does not produce sparks, risks of sparks/heat are reduced even in fault conditions. Used in terminal boxes, junction boxes, and some alarm devices.

Ex t (dust protection): Enclosure-based protection in dust atmospheres (EN 60079-31). Critical for sirens/flashers in dusty processes.

Ex m, Ex p, Ex n: Less common but defined for specific applications.

Protection type must always be considered together with the zone and device class. For example, in a Zone 0 gas atmosphere, Ex ia intrinsically safe detectors and call points are selected, while in Zone 1, Ex ib or Ex d devices may be used.

Examples Marking:

II 2G Ex db IIC T4 Gb

II: Surface industries (non-mining)

2G: Category 2, gas → suitable for Zone 1

Ex db: Flameproof enclosure

IIC: Suitable for most hazardous gases (hydrogen, acetylene)

T4: Max surface temp 135 °C

Gb: High protection level

Such a beacon-sounder with this marking can be safely used in an LPG filling plant in Zone 1.

II 1D Ex ia IIIC T85°C Da

II: Surface industry (non-mining)

1D: Category 1, dust atmosphere → can be used in Zone 20 (continuous explosive dust atmosphere)

Ex ia: Intrinsically safe (highest protection level)

IIIC: Suitable for conductive dusts (e.g., metal dusts)

T85°C: Device surface temperature limited to 85 °C

Da: Very high protection level for dust (Equipment Protection Level)

A heat detector with this marking can be safely used in a metal processing facility with aluminum dust (Zone 20).

Fire Detection and Alarm Devices: EN 54 vs ATEX

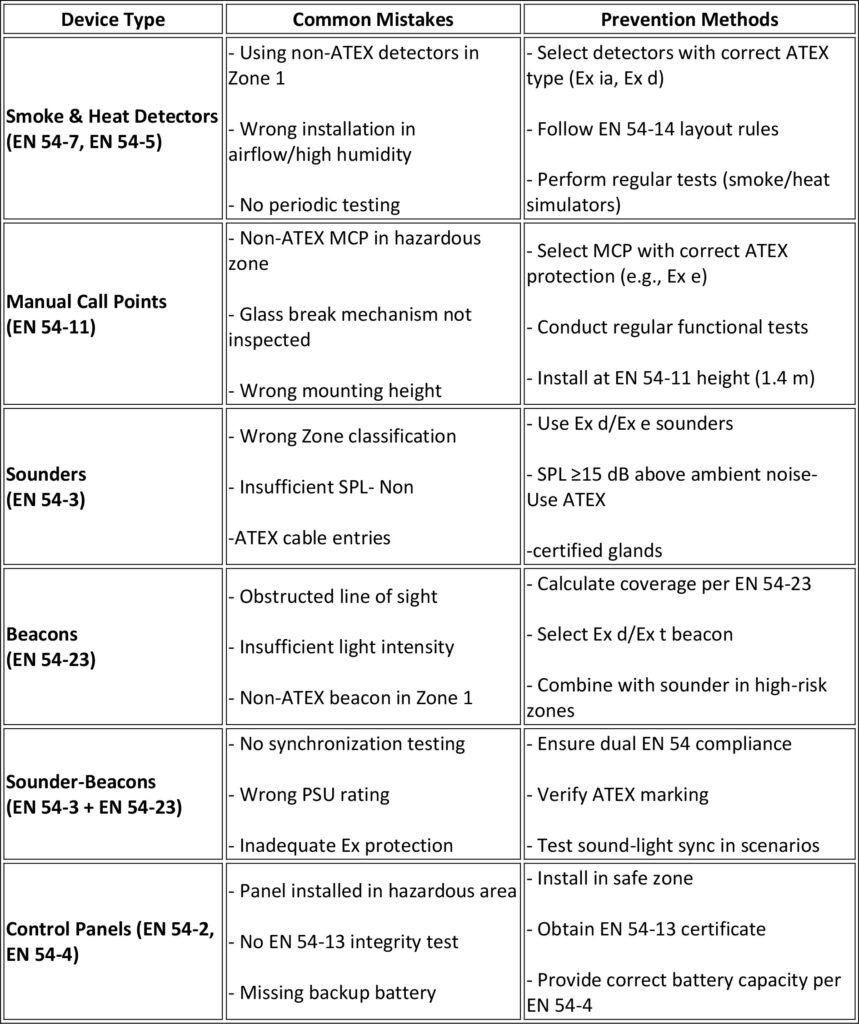

Each device must comply with both EN 54 and ATEX requirements.